Quality

Our strength and goodwill is our product Quality. Our client has appreciated our Quality. For the Quality assurance we follow our ISO 9001:2015 QMS (Quality Management System). Our material is complying the requirement of RoHS which statutory requirement in Europe. Our Product complying international standards like DIN, BS, ASTM, etc. We conduct Quality test of the product. We have done the laboratory Test of Composition (CuZn39Pb3, Free cutting Brass, Forging Standards, etc.). In case the client required Test.

We conduct impact test, torque test, hardness test, humidity tests, Plating thickness test&Degree verification test in any recognized Mechanical laboratory. We provide thread of different type like → BA, BSW, BS Fine, BSP Parallel and Taper, Metric Thread, etc.

Training : It is all time practice of the company to train the entire staff at the regular interval. To keep updated the strength of the company to produce the excellent Quality of the Products. To meet the highest level of the customer satisfaction as all the time.

Machines : Company has Conventional and semi conventional machinery to produce good Quality of Products.

Inspection : Company has unique Inspection facility to achieve goal to zero defects and rejection of any Products. We have well experienced and regularly trained, technocrat engineers, carry out the Inspection on each Individual Products.

Instruments : Instruments are the heartbeats of Quality Products, to assure good Quality product always have competent Instruments are required. Company has invested good amount behind the Inspection instruments. We have all general purpose instruments and gauges along with the profile projector.

Calibrating : Each and every Instrument and Gauges are periodically calibrated, to ensure integrity of measurement preventive.

- TPM will increase productivity and can boost Overall Plant Efficiency by 50 to 100%.

- It can reduce the deviations in the products and thereby almost eliminate customer complaints.

- TPM has potentials to bring down Maintenance cost by one third to that of before TPM.

- Takes the team spirit of organization to a new level and ensures successful implementation of other Lean Systems.

- Plant machineries and utilities are maintained as good as OEM condition with minimum cost.

Our REACH compliant precision components meet all specifications of this registration by providing chemical information from manufacturers to our customers.

Standards and Requirements RoHS Compliant precision components

The Restriction of Hazardous Substances (RoHS) is a directive that originated in the European Union and outlines the restriction of 10 hazardous materials that are commonly found in electrical and electronic products. The goal of establishing these requirements is to address consumer waste by restricting chemicals that pose an occupational danger during manufacturing and pollute the environment.

For a manufacturer, distributor or reseller to meet RoHS compliance they must not utilize any of the hazardous materials that are banned under these requirements. The list originally contained six hazardous substances but was recently expanded to 10.

RoHS compliant precision components are now required to be free of: Lead, Mercury, Cadmium, Hexavalent Chromium, Polybrominated Biphenyls, Polybrominated Diphenyl Ethers, Bis(2-Ethylhexyl) phthalate, Benzyl butyl phthalate, Dibutyl phthalate, and Diisobutyl phthalate. Per standards, the maximum allowable levels for these materials are 0.1% or 1000 ppm by weight.

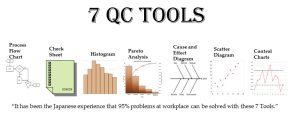

The major benefits of QC tools are:

- To analyze and solve quality problems effectively.

- Improve product and process quality.

- Enhance customer satisfaction.

- Reduce cost due to poor quality.

- Helps in investigating the potential causes and real root cause of the problem for taking effective countermeasures.

- Check sheet helps in data collection and recording for quality problem analysis.

- Identify and reduce the process variation using the SPC quality tool.

- Pareto QC tool helps to narrow down the quality problem using the 80/20 rule.

- Helps in identifying the various sources of variations present in the process.

- Improve the employee’s analytical and problem-solving skills.